Have you ever really looked at the “skin” of your clothes—the fabric? Those soft, crisp, breathable, or waterproof materials, how exactly do they come into being? Today, we’re unlocking the “hidden files” of fabric to discover how much science and craftsmanship lie within this seemingly ordinary material.

The “Past and Present” of Fabric: Starting from a Single Fiber

The story of fabric begins with “fibers.” Just as a house needs bricks, the “bricks” of fabric are fibers. Some come from nature, others are the product of human ingenuity.

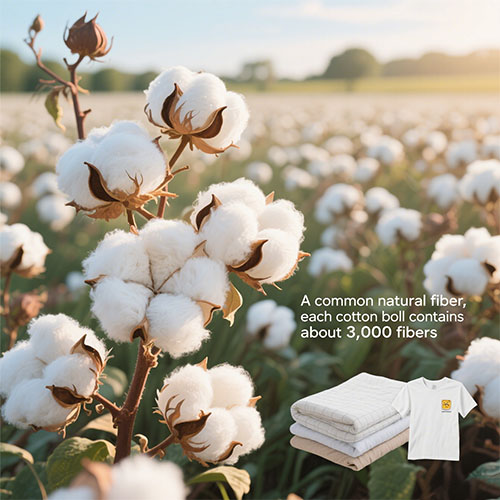

Natural Fibers: Gifts from Nature

Cotton is one of the most common natural fibers. A single cotton boll contains about 3,000 fibers, each stretching 3-5 centimeters—their flexibility rivals that of thin steel wire. The T-shirts and bed sheets you wear are likely made with it.

Wool is the “warmth master of the animal kingdom.” Each wool fiber has countless scales that interlock, giving wool its natural “felting property”—which is why wool sweaters shrink if not washed properly. Silk, meanwhile, is extraordinary: a single cocoon is made of one continuous thread, up to 1,500 meters long, earning it the title of “nature’s long-fiber champion.” Silk woven from it is so light it can pass through a ring.

Man-Made Fibers: Human “Creation Magic”

Polyester is the “workhorse” of man-made fibers—durable, wrinkle-resistant, and affordable, it’s the backbone of many sportswear and curtains. Spandex (Lycra), on the other hand, is the “elasticity expert,” stretching 5-8 times its original length. Adding a little to jeans or yoga clothes instantly boosts comfort.

Then there are the trending “recycled fibers,” like recycled polyester made from plastic bottles. One ton of recycled fiber can save about 60,000 plastic bottles, making it both eco-friendly and practical—a rising star in the fashion world.

Weaving Determines Character: The Same Fiber, a Thousand Looks

Fibers are just “raw materials”; to become fabric, they need the key process of “weaving.” Like Lego bricks that can form endless shapes, different weaving methods give fabric entirely different personalities.

Woven Fabrics: The “Precise Type” of Interlacing Warp and Weft

The most common method is “weaving”—warp threads (longitudinal) and weft threads (horizontal) interlace like cross-stitch. Plain weave (e.g., shirt fabric) has uniform interlacing, making it durable but slightly stiff. Twill weave (e.g., denim) interlaces at 45 degrees, creating visible diagonal lines for a soft yet structured feel. Satin weave (e.g., silk) lets warp or weft threads float on the surface, resulting in a smooth, mirror-like texture that exudes luxury.

Knitted Fabrics: The “Flexible Type” of Interlocking Loops

If you’ve touched a sweater or hoodie, you’ll notice their exceptional elasticity. That’s because knitted fabrics are made of countless interlocking loops, like a chain of links that stretch freely. Common “knitted cotton” and “ribbed fabric” belong to this family—perfect for close-fitting.

Non-Woven Fabrics: The “Quick Type” That Skips Weaving

Some fabrics don’t even need weaving. Materials like the melt-blown fabric in masks or disposable bed sheets are made by bonding or heat-pressing fibers directly into cloth. They’re fast to produce and low-cost but less strong, ideal for one-time use.

The “Special Skills” of Fabric: Technology Makes It More Than Just Cloth

Today’s fabrics are far beyond “covering and warming.” Technology has given them incredible “superpowers.”

Breathable Fabrics

Some fabrics have countless micron-sized pores that let sweat escape as vapor while blocking external moisture. Take Gore-Tex, used in outdoor jackets—stay dry even in rain.

Temperature-Regulating Fabrics

Fabrics with “phase-change materials” act like built-in air conditioners: they absorb heat and turn liquid when warm, then release heat and solidify when cool, keeping your body comfortable. Look for them in winter thermal underwear or summer cooling T-shirts.

“Talking” Smart Fabrics

Weaving sensors into fabric creates “smart clothing.” Sportswear can monitor heart rate and breathing; medical uniforms transmit patients’ vital signs in real time. There’s even fabric that generates electricity—wear it to charge your phone. The future is here!

Choose the Right Fabric, Wear the Right Clothes: Tips to Avoid Mistakes

Understanding fabric labels when shopping for clothes can save you trouble:

For close-to-skin wear, choose breathable, moisture-absorbing fabrics like cotton, silk, or modal.

Outerwear suits durable, wind-resistant fabrics like polyester or nylon.

For stretchy clothes (e.g., leggings, sportswear), check the spandex content—5%-10% is usually enough.

Natural fabrics like wool and cashmere are moth-prone; store them with camphor and avoid washing (they’ll shrink!)

A piece of fabric travels from cotton fields and silkworm cocoons to factory looms, designer scissors, and finally to us, carrying warmth and stories. Next time you put on clothes, feel their texture and imagine their journey—turns out we’re surrounded by so much “technology and craftsmanship” every day!

Post time: Jul-03-2025